It might be said that Nova Scotia's apple industry had its roots in the early 1600s when the French settlers brought fruit trees with them to Port Royal. It became a sapling in the late 1700s when the New England planters brought new varieties into the province. But the industry reached its maturity when the grandfather of Nova Scotia's apple industry, Charles Ramage Prescott, began sharing grafting stock and young plants, including those for the well-loved Gravenstein. All these horticultural steps established the orchards of Kings and Annapolis Counties, where the vibrant industry exists today.

In these two counties alone there are 2600 hectares of land planted with apples, and they produce 2.5 million bushels per annum, which amounts to 10 per cent of Canada's total production.

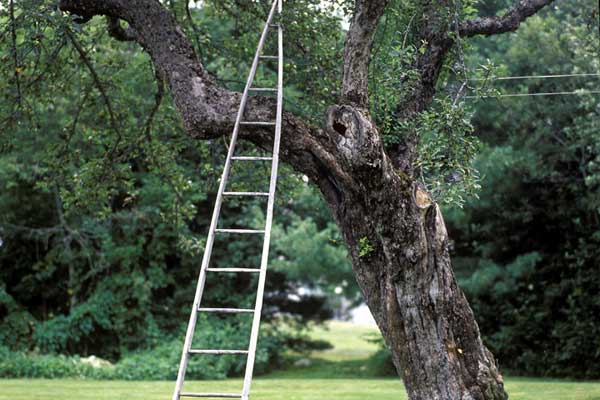

Changes have occurred over the years. There is no longer a demand for the thousands of cooper's barrels that were once used, nor the hundreds of Mi'kmaq baskets or the funky-looking apple ladders with the pointed tops, which were craftily designed for secure propping against knobby tree limbs. So, these traditional items are now seen as craft rather than industry. Their charm remains irrefutable, however, and perhaps their uses are now more varied because they are inspired by sentiment rather than practicality. Apple ladders can hang on a wall, decorated with dried flowers; can be used as a towel rail in a bathroom or as a rack for a child's stuffed toys; or just lean yours against the old apple tree in the front yard.

Making one is not simple, but neither is it rocket science, and anyone with some basic tools and skills is more than able. Perhaps the hardest thing will be finding the spruce pole to begin. However, woodlots, and building lots are plentiful and folk are friendly. In Nova Scotia, you could give Windhorse Farm or Maple Creek Ecoforestry a call.

Tools:

- Electric drill with a 1/8" bit, a 1/4" bit, and a set of forstner bits, or spade bits.

- Square

- Bevel gauge

- Protractor

- Froe and hardwood mallet

- Drawknife

- Spoke Shave

- 1/4" dowel

- C-Clamp

- Nut, bolt and washers and 2 adjustable wrenches, OR copper nails, ball peen hammer, nippers, and heavy steel backing mallet (length to be determined by the dimensions of the ladder sides)

- Drill bit of same size as bolt, or copper nails.

- Carpenter's glue (optional)

- Various blocks of wood, softwood and hardwood

- Sandpaper and Tung oil

Step One: Find a slow-growing spruce that is as straight and knot free as possible, is 5"-6" in diameter at the butt, and is slightly taller than the length of ladder you wish to make.

Step Two: Clean off the bark using a drawknife, and put your pole on the cool floor of your shed, garage, or basement, to dry for several months. Note: For those with a thirst for technicalities, here on the east coast, relative humidity of your wood should be 15-20 per cent before beginning.

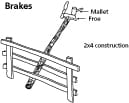

Step Three: When you have waited long enough, rip the tree in half lengthways. This can be done with either a two-man ripsaw, or a froe, where the tree is rived apart. It is believed that riving results in a stronger working piece because the split you make follows the cellular structure of the wood, so use one if you can. Whichever way you select; begin by constructing a brake to hold your timber firmly (see diagrams below).

Note: Froes are available at the hardware store. However, if you know a blacksmith, having one made is more interesting and will give you a better tool. A piece of flat steel bar stock is beveled on one edge and an eye made at one end. This is fabricated either by bending a loop and forge, welding it back against the blade, or by welding a short piece of pipe to one end of the mild steel bar. The lower edge is then sharpened and a hardwood handle securely attached through the eye. The froe is used by striking the back of the blade with a club shaped from a piece of firewood, the handle carved to fit your hand, and perhaps even with a knot at the top to strike with. Barring this, a hardwood mallet will do the job.

Follow these three simple rules: 1. Locate your split with even internal pressure on both sides, so rive a piece in half, and then in half again until you reach the dimension you require. 2. Follow through with each split. Trying to redirect a misdirected split will only result in a double one. 3. Always try to rive as close to the finished dimensions as possible to save time in shaping later.

Step Four: Now, back to the ladder. Bind the sides together once more, keeping the ends even. Using a square as a guide, drill marker holes in both pieces at 12" intervals starting at the base. These are to space the rungs evenly and level.

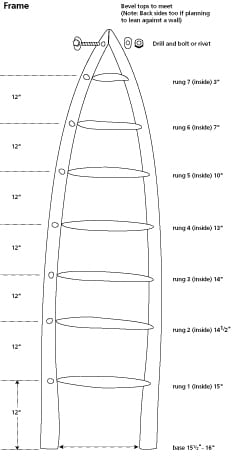

Step Five: The tops of the ladder will be brought to a point later so the ends must be beveled. Begin at 35-40 degrees, as this will leave some room for final adjustment.

Note: There are several schools of thought about whether the rungs should be softwood or hardwood. Some say the hardwood becomes slippery beneath a dew-laden boot; however, toughness is important. This is a wood's capacity to withstand suddenly applied loads. From the Forest Products Laboratory table we learn that the following species fall in the High category for toughness: ash, beech, birch (yellow), dogwood, elm (all), hackberry, hickory, hornbeam, ironwood, locust (black and honey), maple (sugar), oak (all), osage orange, pecan, persimmon, walnut. Any of these are suitable for rungs. Nice straight-grained hardwood from a firewood pile will suffice.

Step Six: Use a froe to rive out the 2" stock you need for rungs and put it up to dry. The bottom rung on your eight foot ladder should measure 15", the second = 14 1/2", third = 14", etc., so add the diameter of your ladder legs to the measurements shown, giving yourself a little extra for safety, and cut your stock to length. See the diagram as guide.

Note: ideally, to make a tight "green" joint you should put a dry tenon into a wet mortise so that the mortise will shrink onto the tenon as it dries, and the tenon will swell as it absorbs moisture from the sides of the ladder. Patience is the key to all successful drying. Start by air-drying your wood for several days. This prevents checking, warping and interior honeycombing. One method for further drying is to place your rungs on a wire rack over your woodstove, or gas water heater. For those who might have use of a kiln for other projects, one can be constructed from a 55-gallon steel drum in which the wood can be stickered and stacked.

A 500-watt radiant lamp mounted in a chick brooder socket, with a curved aluminum reflector above it would suffice as the heat source. 120-140 degrees should be maintained. Lower temperatures will work but they will lengthen the drying process. Technical note: 5-7 per cent moisture content is ideal.

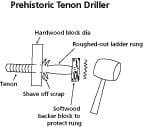

Step Seven: Once your roughed out wood is dry, clamp it into a vice, (a method for doing this is shown) or shaving horse, and use a draw knife to fashion cigar-shaped dowels of decreasing length, and of the number your ladder requires. Finish them to size with a spoke shave. Make the tenons long and a uniform 1" to 1 1/2" in diameter, and the centers of each rung 1 1/2" to 1 3/4" thick for added strength.

Note: A simple tenon sizing technique is to bore mortise-sized holes in a piece of scrap hardwood, shave your tenons to a close fit, then drive them into the mock mortise with a mallet. This will size your tenons perfectly. Trim off the shoulders.

Step Eight: Bore all the mortises so that the tops of the rungs will be spaced 12" apart. Use your predrilled guide holes as just that, guides. Use a square to keep the holes 90 degrees to the sides for the bottom four rungs. Use a bevel gauge set to approximately 70 degrees to line up your drill for the mortises for the top three rungs.

Step Nine: Fit the rungs, shortest at the top, longest at the bottom. Pound each rung into place using a sacrificial softwood block to protect your tenons. Now you have half a ladder.

Step Ten: It is time to find a friend. The second leg must be lined up, tenons into mortises and pounded into place. Expect a bit of a fight with some wiggly, stubborn sticks of wood.

Step Eleven: Draw the top ends together using a Spanish windlass, or a clamp. Shave the bevels as necessary for a good fit, drill, and bolt. Use a washer beneath both the bolt head and the nut. For a more aesthetic look you could make a rivet out of a copper nail. To do this just drill a hole of a size that will allow the copper nail a snug but not tight passage through the wood, nip the end off the nail leaving 1/8 inch. With a heavy weight held securely and square against the nail head, peen the end carefully to make a flattened mushroom. Finish the rivet by peening the nail head itself slightly.

Note: a Spanish windlass is a slick and simple clamping device using a length of rope looped between the two legs, and a stick handle to twist and turn the rope shorter and shorter, which pulls your two pieces together. The only tricky bit is to figure out a way to secure the stick handle while you are working on the ladder because if you just let go it will unwind in a hurry and may be quite dangerous!

Step Twelve: To ensure secure rungs, peg each rung tenon by drilling through the legs and tenons from front to back. Squeeze some waterproof carpenter's glue into the hole and drive a piece of 1/4" hardwood dowel through. Trim the dowels flush. Alternatively, rivet with copper nails. They will quickly turn a green colour.

Step Thirteen: Trim your ladder smooth with a spoke shave for a rustic look, or sand it with 80 or 100 grit sandpaper, just enough to remove any splinters. Apply three coats of tung oil, or a mixture of 50 per cent boiled linseed oil, 50 per cent turpentine. Reapply this finish a couple of times a year for years of happy apple tree climbing.

A final note: Continue to add width at the base if constructing a longer ladder. A ladder maker in Maine even puts a flare at the bottom of some of his products for stability. In Nova Scotia, Keith Scofield, from Hantsport, makes ladders in the summer for sale during apple harvesting season in the fall. So, next time you are at a U-pick in the Annapolis Valley check them out and compare them to the one you have made for yourself.